Cold Room

Cold Room ( know as Chiller Room ) is a walk-in storage facility that maintains a consistent temperature under controlled conditions and is widely used to preserve stored products such as fruits, vegetables, beverages, flowers, beef and chicken quality meat, seafood, medicines, cheese, eggs and other fresh food. Cold room applications include food and beverage packaging, short- and long-term product refrigeration, and blast freezing.

Room Material Specifications

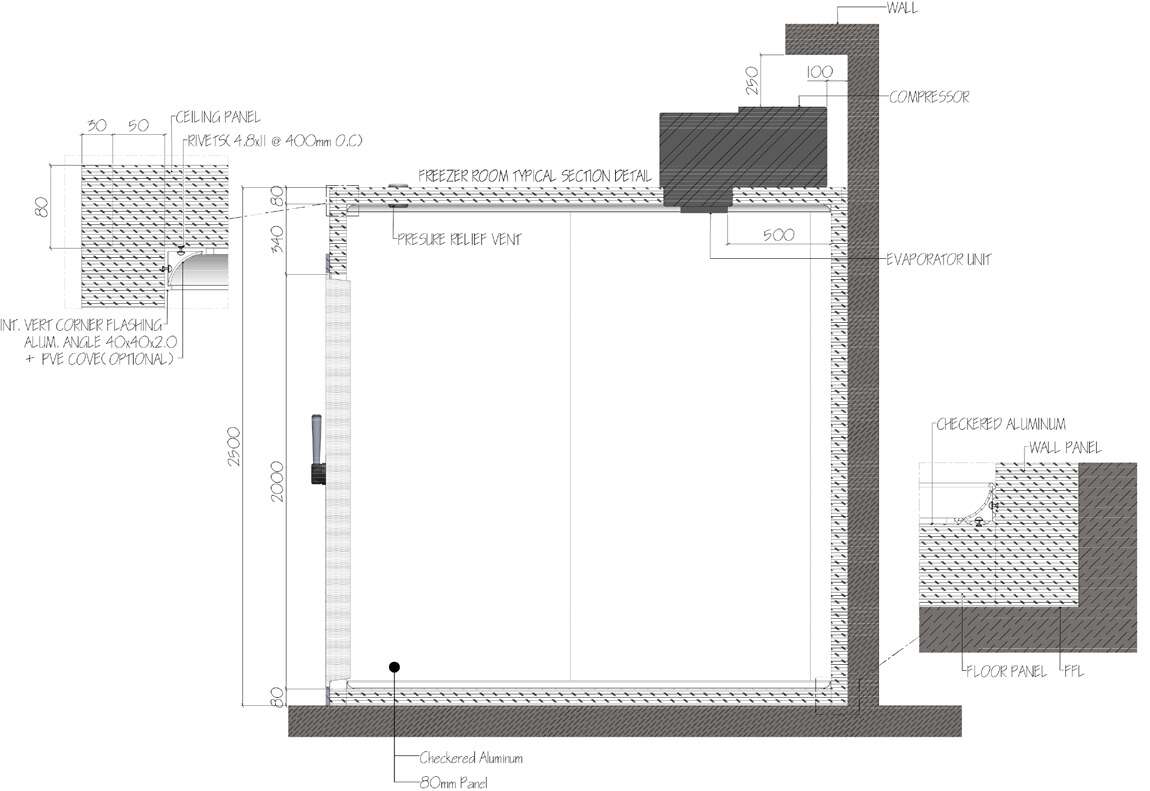

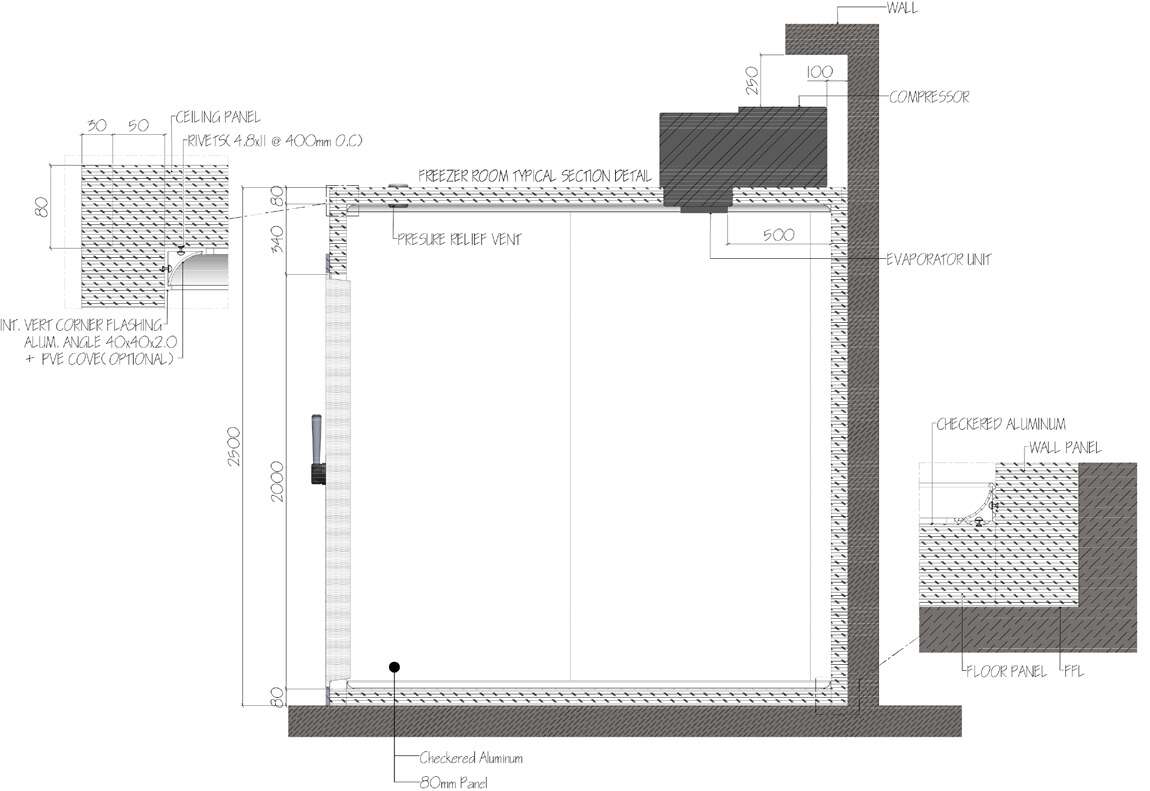

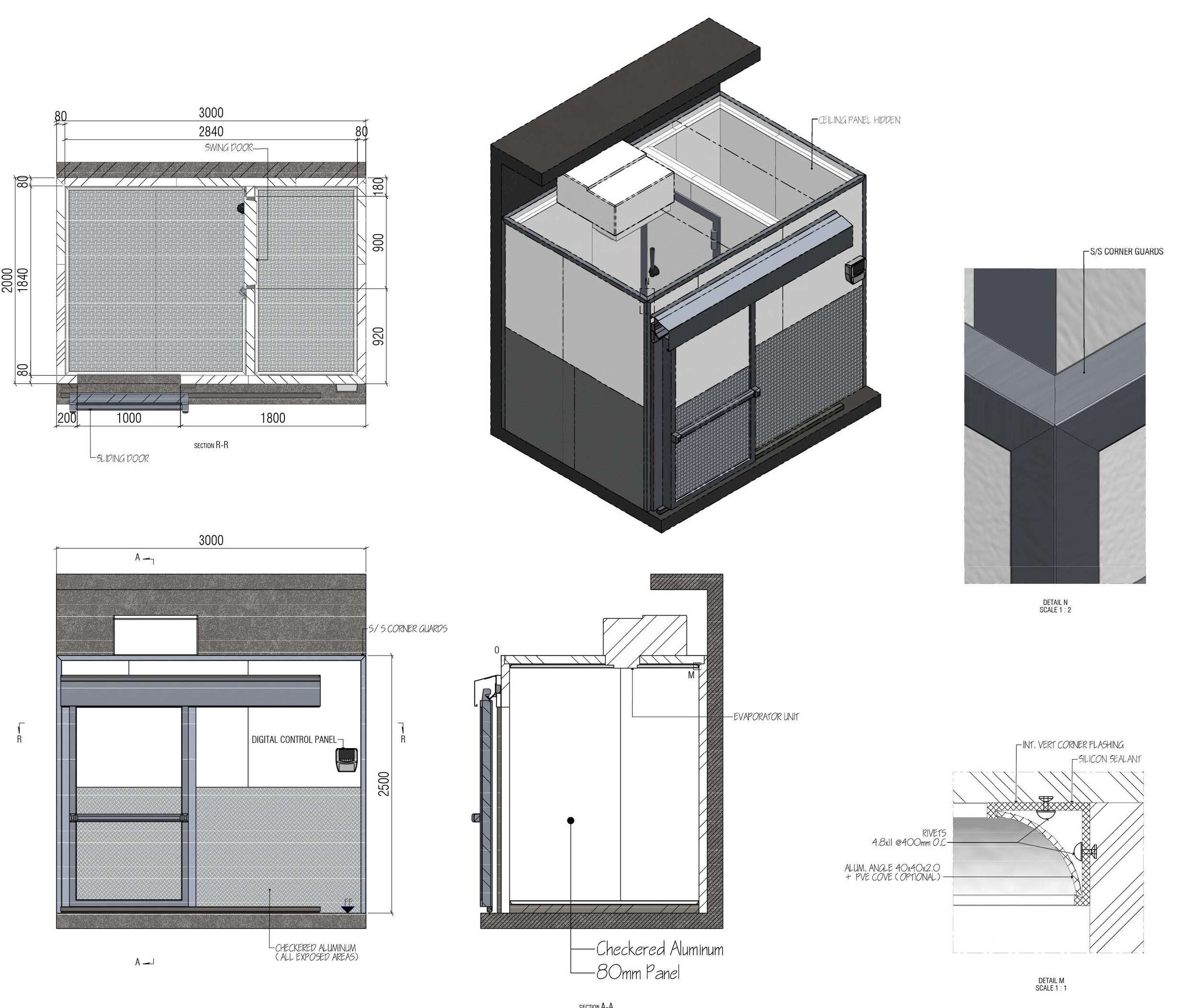

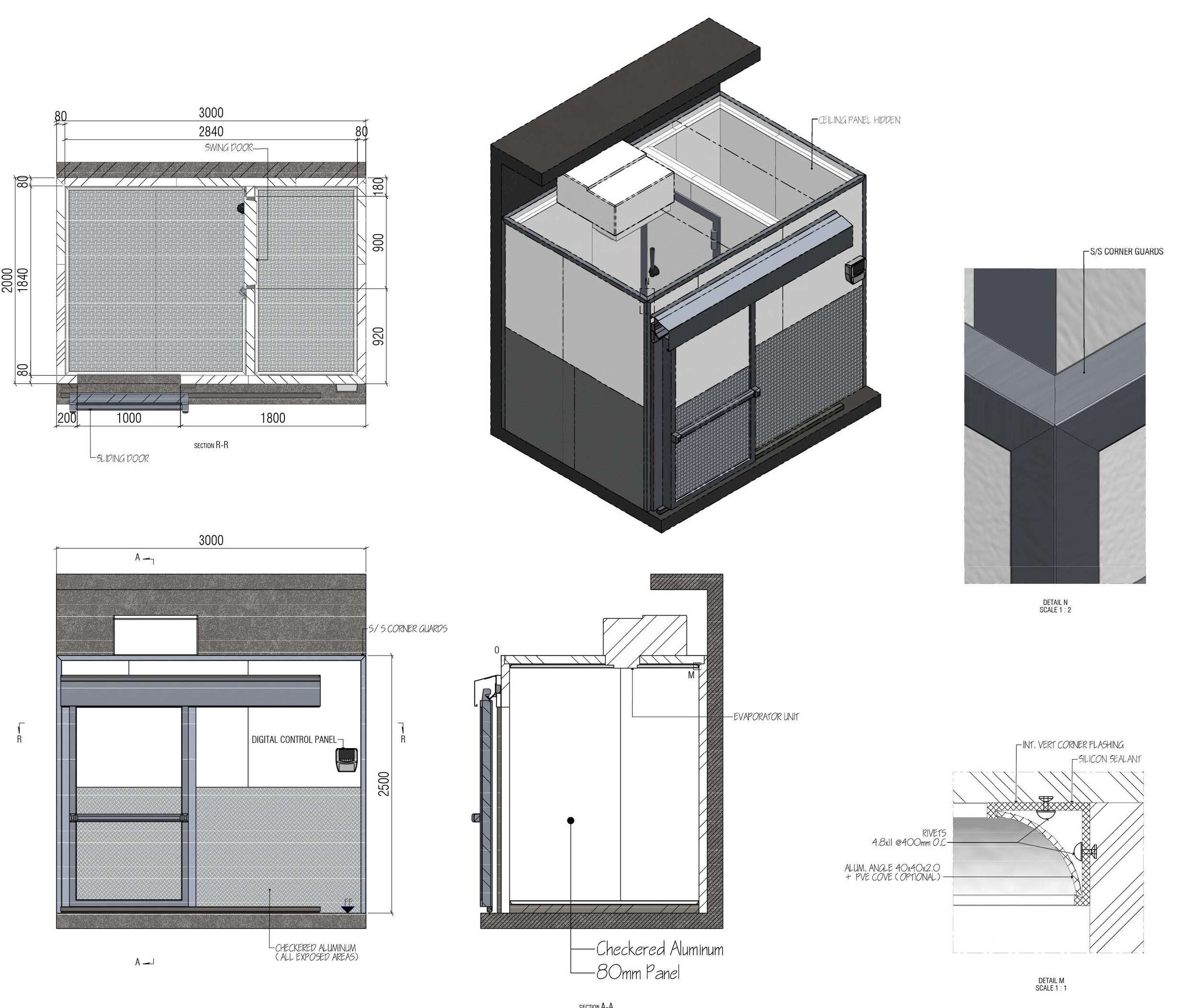

- Insulation: CFC Free, Rigid Injected Polyurethane Foam.

- Density: 42 kg/m3.

- Thickness: 80mm (+0 temp Rooms), 80mm(-0 temp Rooms)

- Cladding: 06 mm P.V.C coating anti-bacterial

- Fire Rating: Meets redundancy requirements based on DIN 4102 class B3 and according to ASTM class B3 and ISO 3582.

- Construction: Panels are joined together by two systems Male-Female + Cam-Lock.

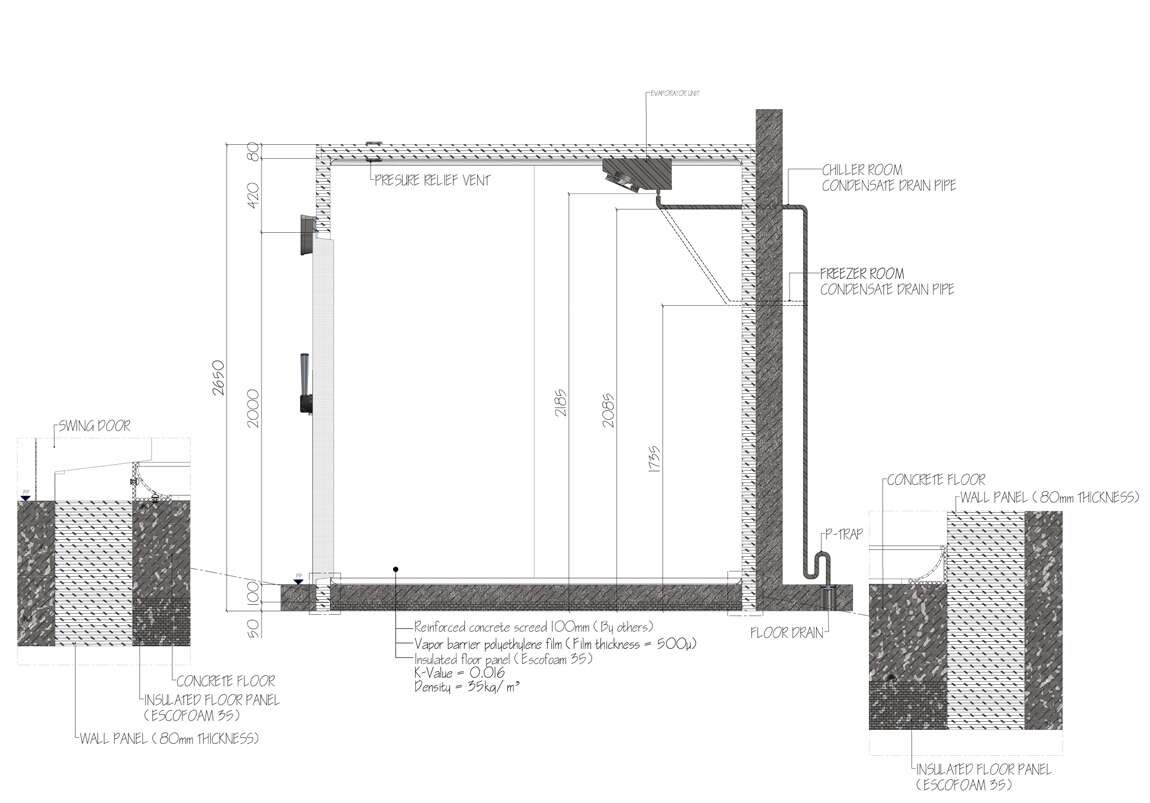

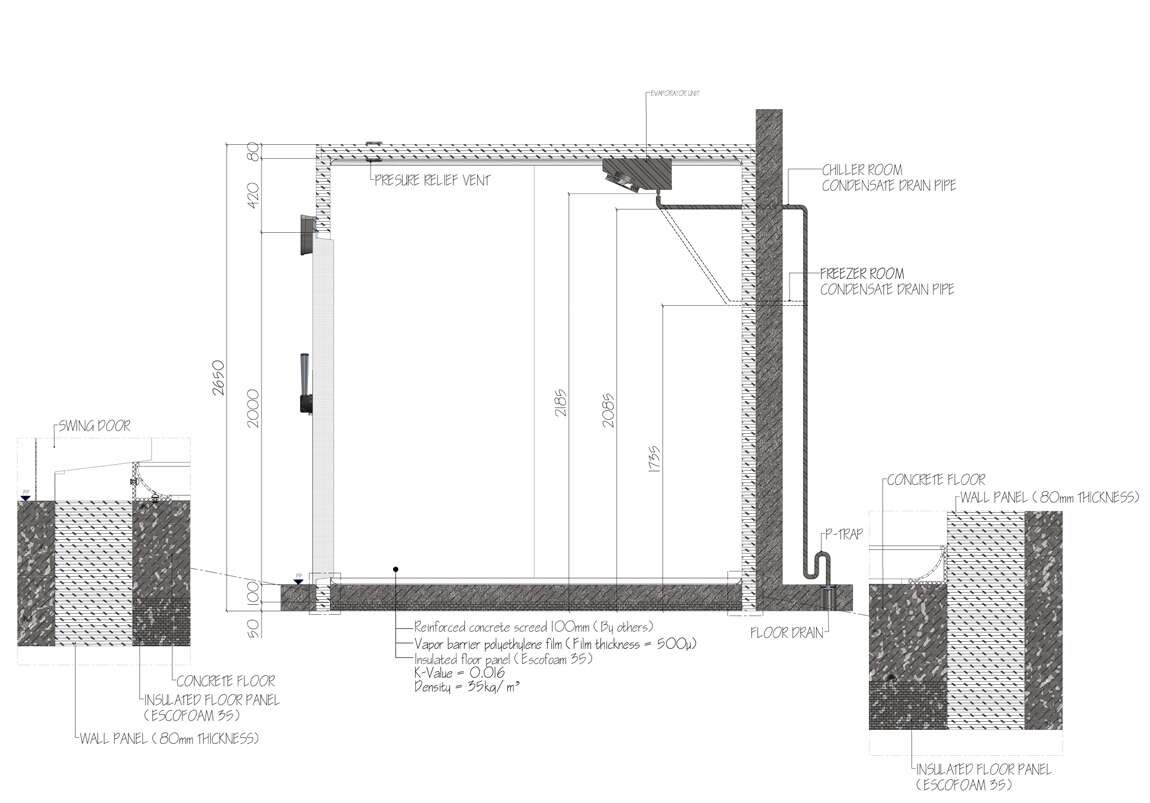

- Flooring: Panel Flooring: 80mm insulated panels with 1.5mm Checkered Aluminum on top Floorless: 50mm insulation foam with 100mm concrete

slab on the top - Doors: To supply single left/right hinged manual doors with. All fittings including rubber gasket Internal Safety Handles are to be standard white or special order of any suitable color to be specified by the client. Door hinges rise the door body as they open so as not to rub the floor, and fall as they close to insure no thermal leakage and full insulation. As a safety measure the door handles illuminate from inside the room to help worker reach to handle immediately if the door suddenly closes and lights go out. Wall-Ceiling Joints are designed with hygienic monolithic arrangement with no sharp edges to avoid an accumulation of dirt and germs (look above PVC cove and angle). o Lighting: Heavy Duty, Water Proof, Low Energy, Florescent Lighting.

- Lighting: Heavy Duty, Water Proof, Low Energy, Florescent Lighting T5.

- Installation: Panels: Pre-Cut as per site dimensions and client requirements. Condensing Units and Evaporators: Pre-Wired to suit site conditions. Installation Time: Installation time is from 1 to 2 days, thanks to Pre-Design works.

Panel Flooring

Floor Less

Cooling Material Specifications

- Condensing units: Zanotti remote unit/Zanotti mono block

- Evaporator: Zanotti made in Italy

- Regrigeramt: R-404

- Electrical Rating: 380v/3ph (unless otherwise specified)

Site Requirment

- Separate electrical circuit breakers for each room’s condensing unit (CP). The circuit breaker needs to be located as per Raqtan electrical design drawing.

- Floor and walls need to be perfectly leveled.

- Condensing unit location must be within 6 meter from evaporator with max 4 meter vertical rise. If need to be higher it must be re evaluated to cover additional material and CU HP costs. CU stand must be installed as per Raqtan drawing**. If CU location will require a crane, it will be expected that it is located in required location before installation.

- All utilities as per Raqtan design to be prepared before installation.

Engineering and Design

- Our Engineering and Design Team studies every cold room order separately.

- Every project will have its own Custom Design and Engineering Work with full layout and electro-mechanical details.